Quality Features

Add More Value to

Your Production

Leadership Through Performance

and Reliability

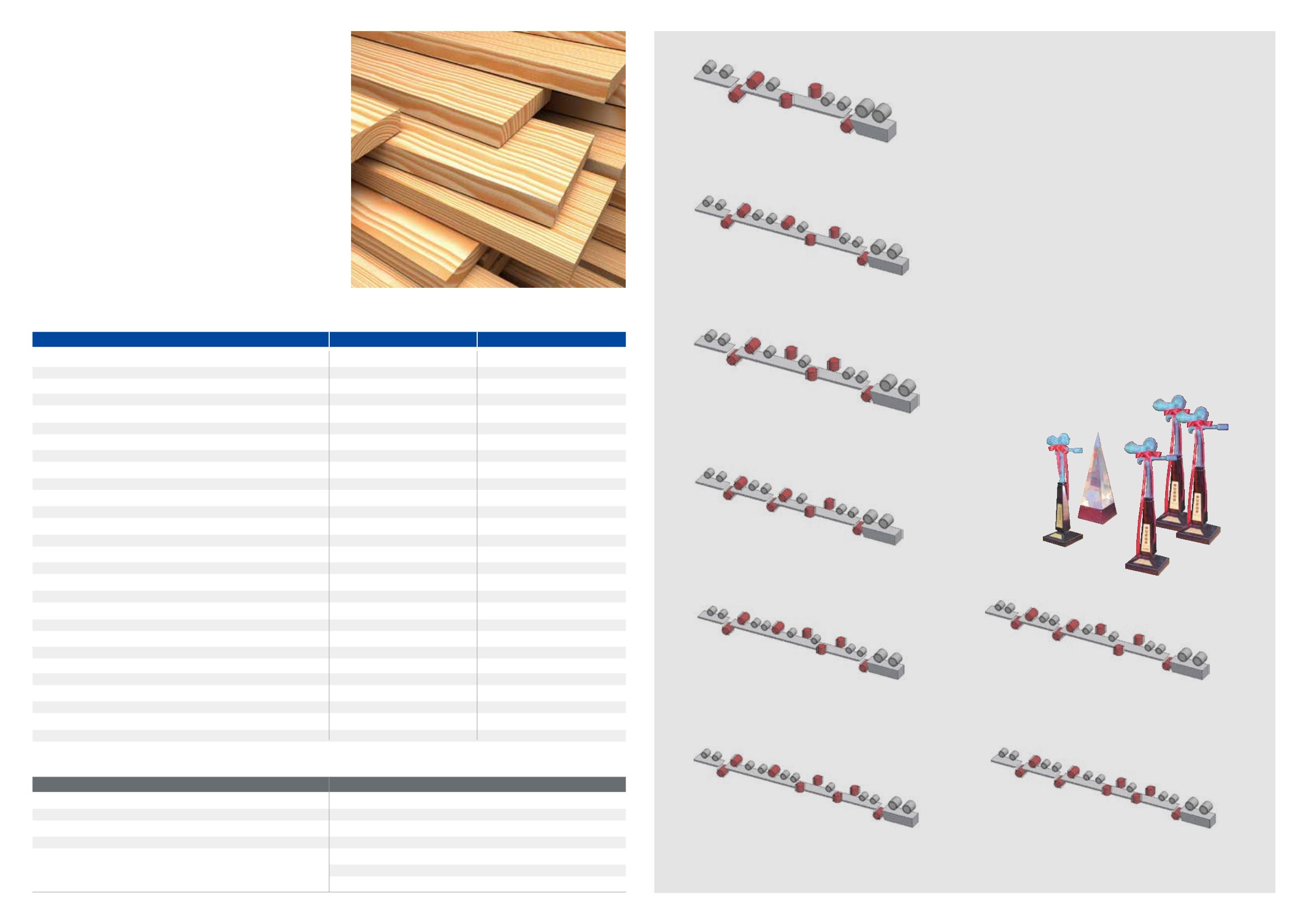

A Wide Range of

Spindle Configurations

(Other configurations available on request)

LEADERMAC's wide variety of 4-side moulders

have all the very latest technology for increased

productivity, product quality & reliability. These

Heavy Duty Moulders are designed to provide fast

cutting speeds and highest quality & accuracy.

These machines are precision manufactured by

our highly skilled technicians - plus Leadermac

service, training, and moulding know-how is

offered with each moulder. No matter what your

moulding jobs call for, there is a Leadermac 4-side

moulder that's right for you.

Spindle configuration

13 / 14

Speedmac series

LEADERMAC

LMC - 3 V - 6 2 3

6 - SP INDLE

L M C - 6 2 3

6 - SP INDLE

L M C - 5 2 3

5 - SP INDLE

LMC - 3 V - 7 2 3

7 - SP INDLE

L M C - 7 2 3

7 - SP INDLE

L M C - 9 2 3

9 - SP INDLE

L M C - 3 V - 8 2 3

8 - SP INDLE

L M C - 8 2 3

8 - SP INDLE

STANDARD EQUIPMENT:

Number of Heads / Spindles, min-max

Working Width (with a tool cutting circle of 163mm)

Working Thickness (with a tool cutting circle of 163mm)

Basic Spindle Motor capacity - Wye-Delta (Soft Starts) on all motors

Spindle Diameter

Spindle Speeds

Tool cutting circle, First Bottom Spindle, min-max

Tool cutting circle, Vertical Spindles, min-max

Tool cutting circle, Horizontal Spindles, min-max

Feed Motor

Feed speed, infinitely variable by frequency (VFD) driven

Top Infeed Rolls - Diameter

other Top Feed Rolls - Diameter

Top Feed Roll Width - Multiple Rolls Stacked on each Top Roll Shaft

Bottom Feed Roll Width

Pneumatic pressure for feed rollers, max

Adjustment range for Infeed Table(Btm Head Cut) and Edge Jointing Fence

Adjustment range of vertical spindles (axial)

Adjustment range of horizontal spindles (axial)

Length of the Infeed / Straightening table

Diameter of Dust Hoods for Vertical & Horizontal Spindles

Digital Readouts on All Axis of all Heads

Digital Readouts for the Chip Breaker Shoes & Pressure Shoes

Full Sound and Safety Enclosure w/ Strobe Free Lighting

Motorized vertical adjustment of Feed Beam

Multiple Lateral Pneumatic Pressure Roller opposite first right spindle

Chainless Extra HD Cardan Shaft Feed System

REC Setworks on Near Side Head(s) & Top(s) - Radial

LMC-223SP to LMC1123SP

Available Options

2 to 11

20-230mm (0.78"-9")

10-150mm (0.39"-6")

11 / 12KW (15HP)

50mm

6000 RPM

125-200mm (5"-7.8")

140-250mm (5.5"-9.8")

140--250mm (5.5"-9.8")

11KW / 15HP / INVERTER

6-60 m/min (20/200fpm)

205.36mm (8")

140mm (5.5")

50mm (2") / Roll

Full Width

6 bar (85psi)

10mm (.4")

80mm (3.2")

40mm (1.6")

0.8M (32")

Ø175mm (6.9")

Std.

Std.

Std.

Std.

Std.

Std.

Std.

Any Head Configuration - available

to 310mm(12.2"), 330mm (13")

to 6mm(.25") to 200 (8")

to 37.5KW / 50HP

1 13 / 16" / 2 1/8"

7200 / 8000 RPM

15 / 18.5KW (20 / 25HP / INVERTER)

9-90m/min (30-300fpm)

1.4 / 2 / 2.5 / 3M (55" / 78" / 98" / 120")

Straight &/or Profile Jointers any heads

Electronic Rotary Encoder Digital Readouts in lieu of mechancial counters

Extra HD Feedworks; Bottom top Head Configuration for rough materail feeding

Tilting Side Heads

Tilting Top Beam, Tilting Feed, Tilting Feedworks, Tilting top Head Chipbreaker Ass'y,

Tilting Pressure Plate(s)

OPTIONAL EQUIPMENT:

Grooved Bed for running very short material

Split Pressure Shoes

Opposed Side Heads

Universal Spindle, tool cutting circle min 125mm, max 200mm

Rip Saw Section with up to 56kw (75HP)

Left (Opposite) Hand Feed

Inverter Motor Cutterhead Brakes

●

All specifications, dimensions and design characteristics are subject to change without notice.