21

accord 25 fx

technical

features

ACCORD 25 FX • ACCORD 25 FXM

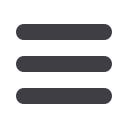

technical data

NUMERIC CONTROL MACHINING CENTRE

AXES

X-Y-Z axes speed

m/min

60 (25) - 60 - 30

MACHINING

AREA X

Bars worktable

mm 3680 - 5020 - 6360

Multi-function worktable

mm

3650 - 4970 - 6170

MACHINING

AREA Y

Bars worktable

mm 1380 - 1680

Multi-function worktable

mm 1320 - 1600 - 2120

WORKPIECE PASSAGE

mm 250

MACHINING

HEAD

3- and 4-axis electrospindle power

kW

12 - 15

5-axis electrospindle power

kW

12

Max. rotation

rpm 24000

TOOL

MAGAZINES

Rear tool magazine

n° pos

16 - 24 - 32

Side tool magazine

n° pos

10 - 12

BORING

UNIT

Vertical and horizontal spindles

n°

from 12 up to 30

Max. rotation

rpm 8000

BRC

Tools for horizontal routing

n°

2

Tools for horizontal boring

n°

4

Tools for vertical boring

n°

3

Blade diam.

mm 300

INSTALLATION

Main suction opening diameter

mm 1 x 250

Additional suction opening diameter

mm 100

Suction air consumption

m

3

/h

4400

Compressed air consumption

NL/min 170 - 300

Machine weight

Kg

6000 - 9000

• Optimum feed speed depending on the material and tool

• Optimisation of compressed air consumption

• Optimisation of vacuum pump speed of rotation, depending on

the vacuum required

• Electrospindle heat exchanger management, depending on the

operating temperature

• Automatic switch to stand-by for motors not being used for machining,

manual or NC

• Opening of the exhaust outlets related to the machining in progress

SAV

E

NERGY

high performance and energy saving